Over 400 GE electronic components on locomotives repaired

“[We have] been very pleased with the high quality, short cycle time for repairs, quick and thorough responsiveness to questions and comments, and the reasonable cost of electronic repair services offered by Electro-Techno.”

– Richard Crowell, Standards Manager, Keolis Commuter Services for the MBTA Commuter Rail Maintenance Contract

Electro-Techno acts as a business partner with Keolis Commuter Services, supporting them in the repair of complex electronic equipment. Since 2018, here is what we have achieved:

- 400 electronic parts repaired

- Full support, as an independent company, of GE components on locomotives

- Repairs made in less than 3 weeks

- Savings of over 60%

- A synergy between Keolis’s technical team and Electro-Techno

Discover how Electro-Techno was able to quickly find solutions to repair electronic components on locomotives, earn Keolis’s trust, and build a partnership.

About Keolis Commuter Services

Since 2014, Keolis Commuter Services operates and maintains the Massachusetts Bay Transportation Authority’s (MBTA) commuter rail system, which carries more than 127,000 passengers daily throughout Greater Boston in the United States.

The MBTA’s commuter trains are powered by diesel-electric locomotives of over 10 years old, which were built by MotivePower Industries (MPI), a subsidiary of Wabtec, with GE electronic parts.

The challenges of maintaining obsolete electronic components

As the damaged parts were obsolete, Keolis was unable to have several propulsion-related components on locomotives repaired by the original equipment manufacturer, GE; the manufacturer’s one-year warranty no longer covered them.

Replacing the electronic components?

The difference in cost between replacing the electronic parts and repairing them is significant: buying new parts is generally 5 times more expensive than repairing them.

The option of having the parts repaired by the manufacturer

One possible option was to get the original parts repaired by the manufacturer. However, this option also caused problems. The lead times to receive and repair the parts can extend over several months, or almost a year. Therefore, Keolis was looking for a cheaper and faster solution.

Refurbishing electronic parts

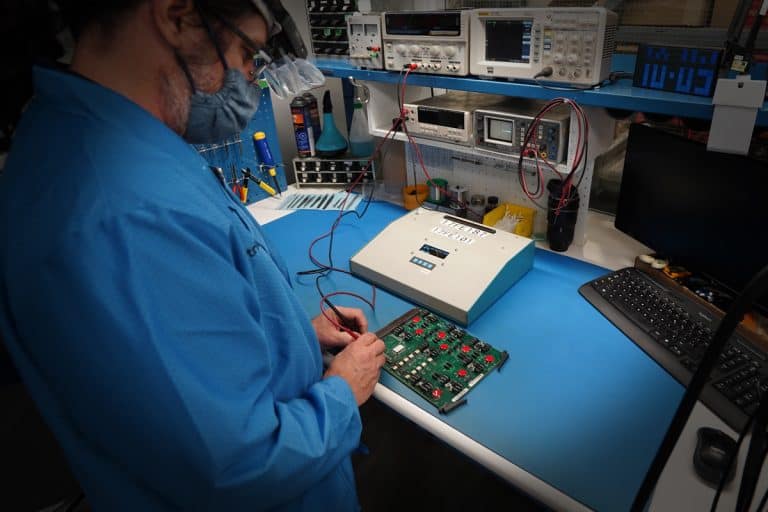

This is why Keolis put its trust in Electro-Techno, an independent repair company, for its refurbishing project. Thanks to the quality of service and repairs as well as the speed of execution, the two companies were able to build a partnership, which began in 2018.

The following parts were fixed, as an independent repair company:

CIO Panels (17FL466 ou 17FL464) | Boards | Others |

17FE102C2 (6 fois) 17FE187A4 (8 fois) | 17FM657A2 17FM704 17FM703 17FM712A1 17FM189 17FM194A3 | 17FH40A1 17FL434 – AUX/HEP PANEL 17FM792A1 – IGBT UNIT / HSP RECTIFIER 17FM724 – AUXILIARY CABINET 17FM740 – ECU PANEL 17FM775A1 – NEGATIVE PANEL 17FM804 – SMART DISPLAY 17FM825 & 17FM826 |

Results

Since 2018, Electro-Techno has repaired over 400 electronic components on locomotives for Keolis.

The average turnaround time for the requested repairs was of just three weeks, much to the customer’s satisfaction.

In addition, a full one-year warranty has been offered on all repairs done. All of the original manufacturer components have been completely refurbished, at a very competitive price. Repairing the damaged electronic components resulted in savings of at least 60%, compared to the purchase of new parts.

Conclusion

There is a reason why we have earned the trust of customers like Keolis: it is because we can offer a fast, efficient, and less expensive solution that is adapted to your needs to repair and refurbish electronic components on locomotives.

If you own or maintain locomotives in service and are experiencing similar issues, please do not hesitate to contact our team for more information on our electronic repair services.